Here are the catalogs from Lemon Tree, welcome to download them after leave your basic info.Hope our professional will helpful for yours.

Applications:It is widely used in purifying factory, combined house, building top attachment, indoor partition, automobile painting room, refrigerator and other projects. E.g.

Interior decoration of civil buildings for medicine, electronics, food stuff beverage, vegetable preservation and large refrigerator etc.

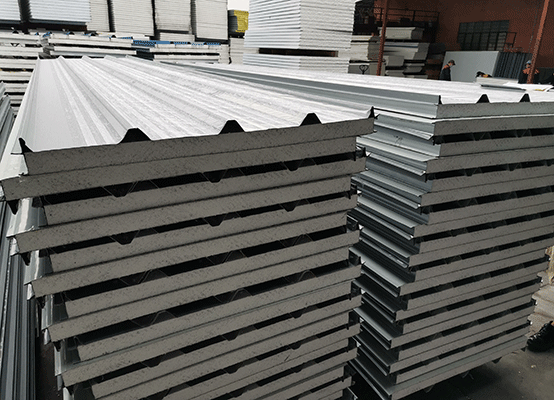

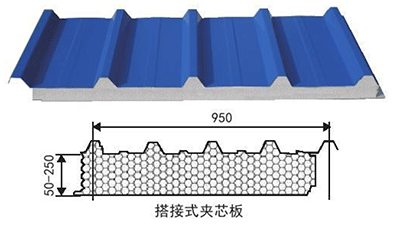

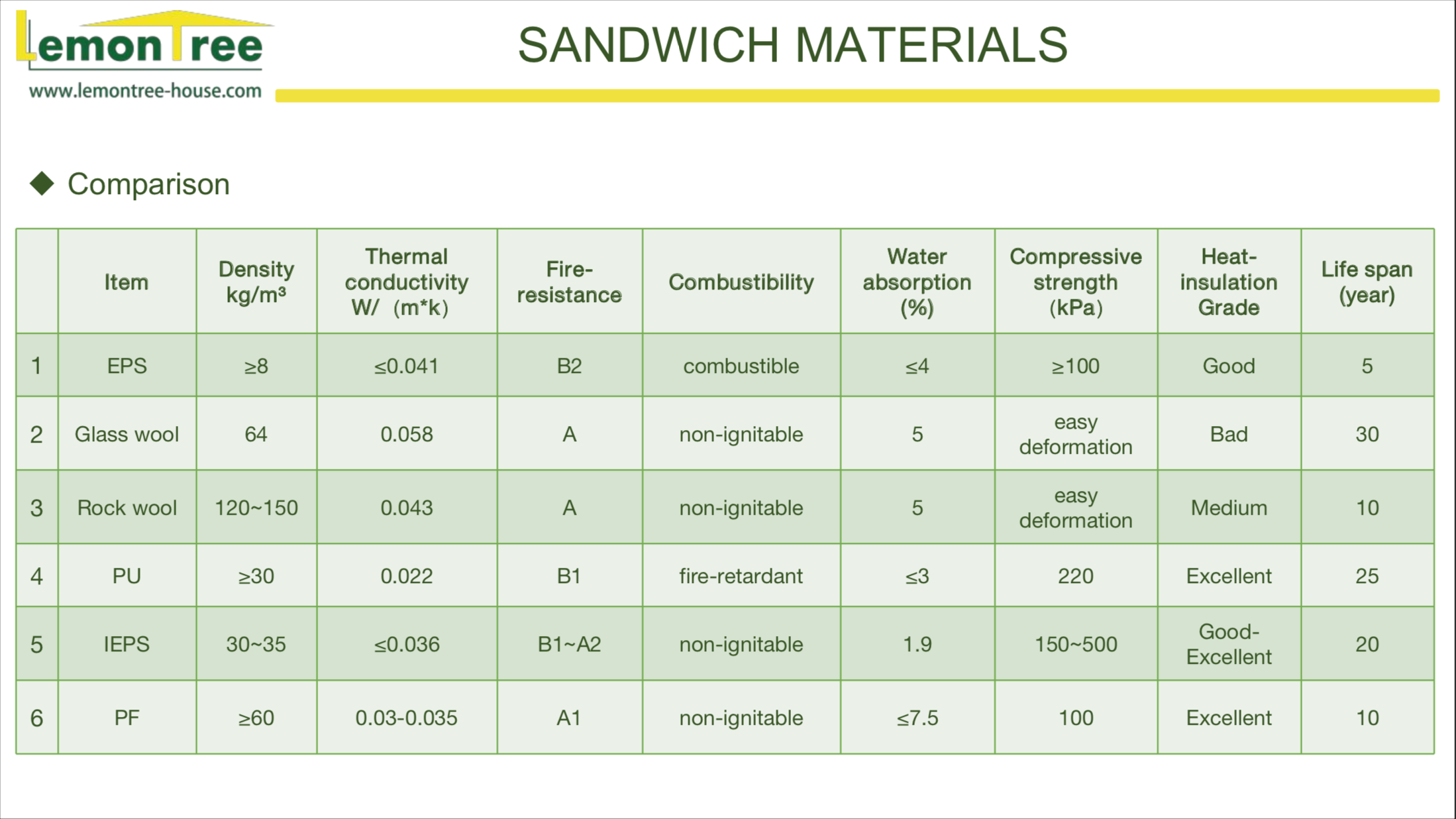

Polystyene sandwich panels ( EPS sandwich panel) is a new kind of building material. It is made up of two pieces of steel sheets with polystrene in, between which are pressed and humidified by computer-controlled color steel moulding machine first and then combined by extra-strong adhesive.

Features: light weight, 10-14kg/m3, easy and fast to install, low cost, strong load ability. Its main thickness are 50mm, 75mm and 100mm respectively while its length can be designed according to the project's requirements and transportation conditions. EPS sandwich panel is charaterized by heat insulation, sound insulation and good moisture retention. Its average thermal coefficiency is 0.032 Kilocalorie/M.H. ℃.

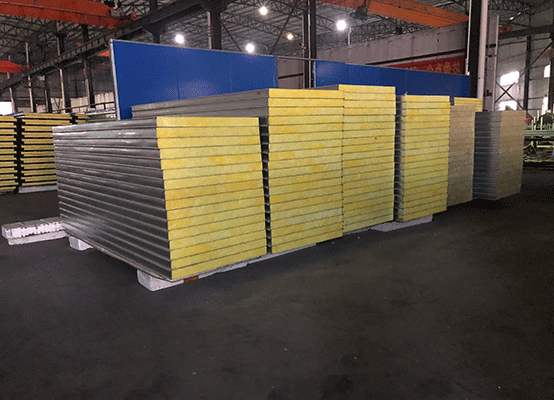

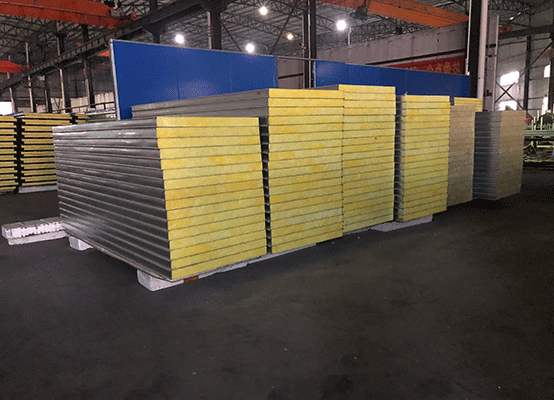

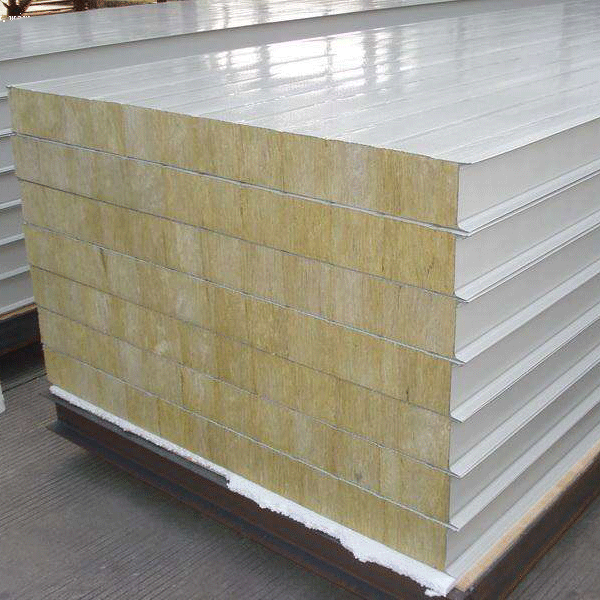

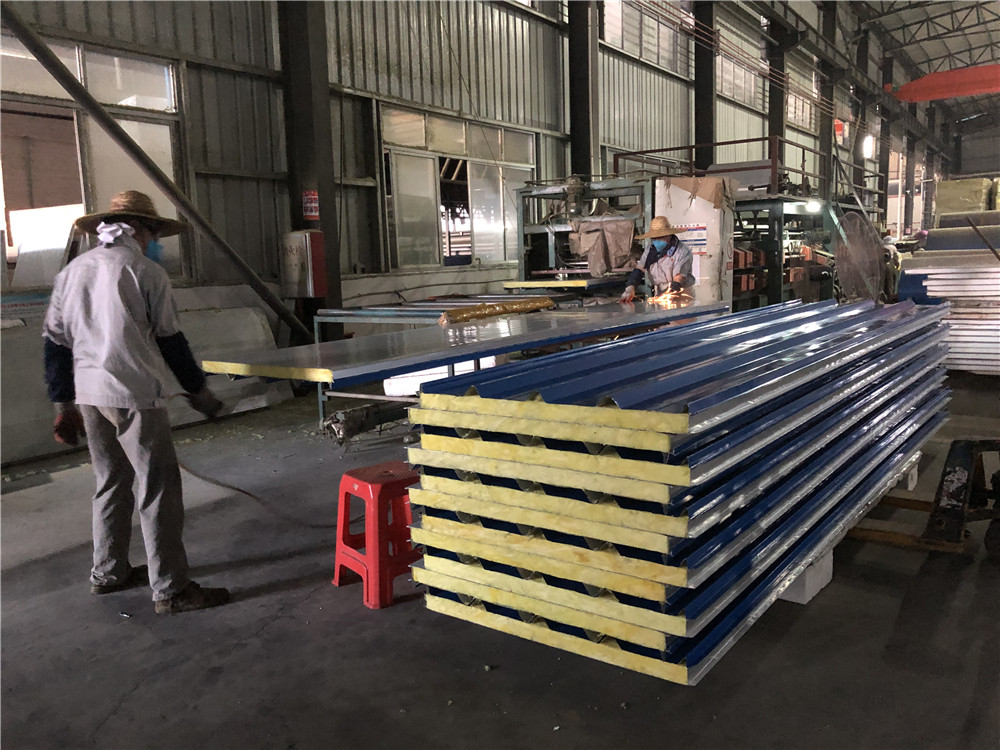

Rock Wool Sandwich Panel

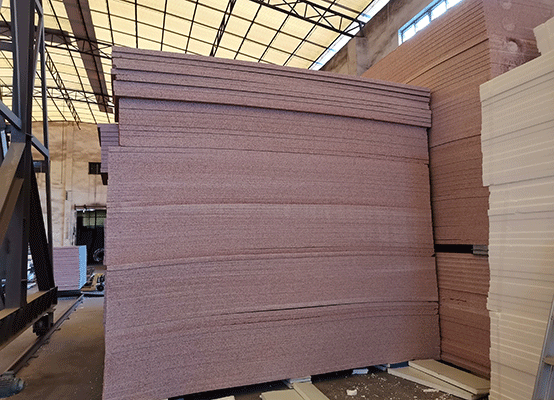

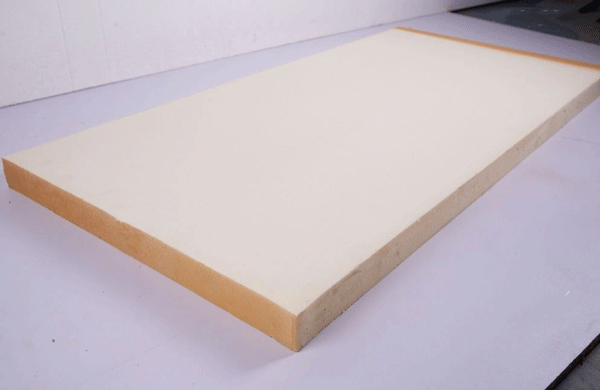

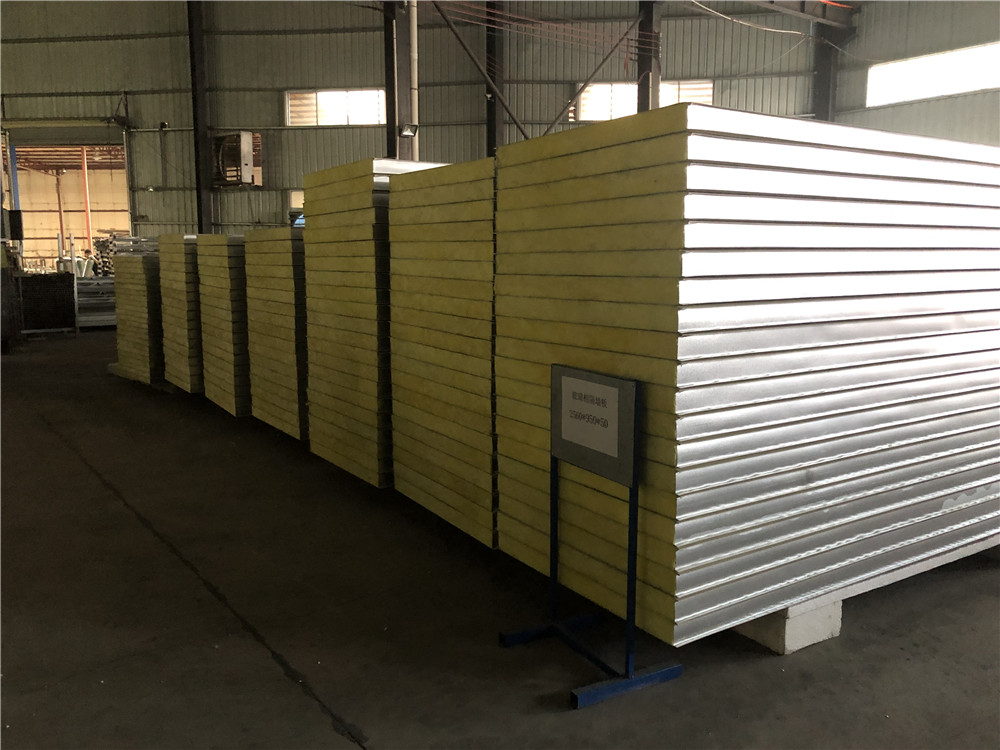

Polyurthane rigid foam is the main raw material of isocyanate and ployether as the main raw material, under the influence of foaming agent, catalyst, flame retardant, etc., through the special equipment mixed with high pressure spray on the field of polymer. Thermal isulation, heat insulation, energy saving (the low thermal condutivity, only 0.022~0.033W/(m*k), fireproof grade: B1.)

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.