Here are the catalogs from Lemon Tree, welcome to download them after leave your basic info.Hope our professional will helpful for yours.

Advantage: The outlook is more beautiful, the interior arrangement more flexible, the sound insulation and heat insulation with better performance due to modular T-house without visible column of (external) surface. It is a better choice to use for office of construction companies and display room.

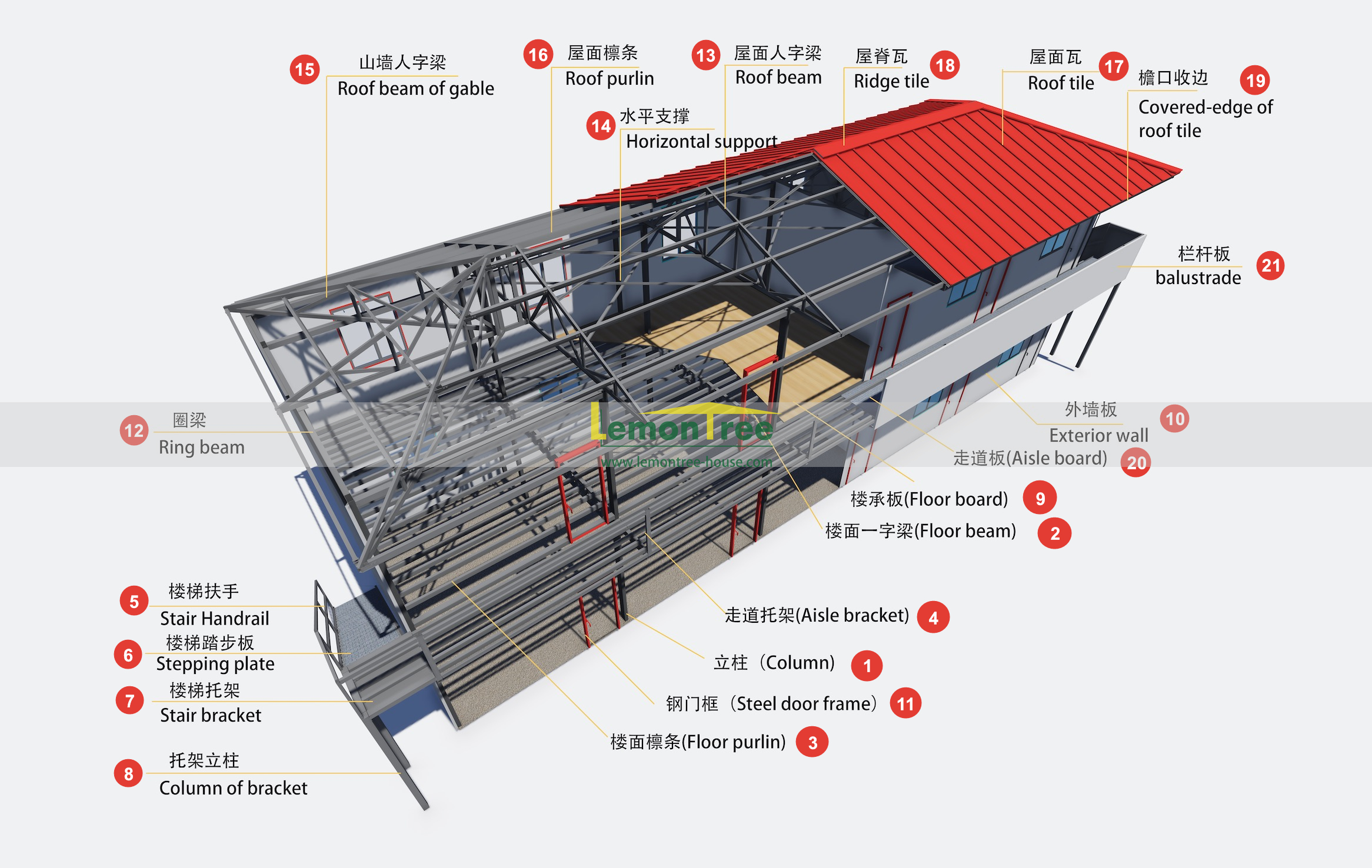

Modular Prefab T House

Following customer requirements to design, then all of T-house’ components are processed and finished at workshop, at last deliver them to site and set them up. It can shorten construction period and also can protect the working environment.

Application: It is widely applied to use as temporary house for engineering camps, government arrangement buildings, large-scale games and commercial events, etc.

Here is a basic material list for Prefabricated T-house for reference.

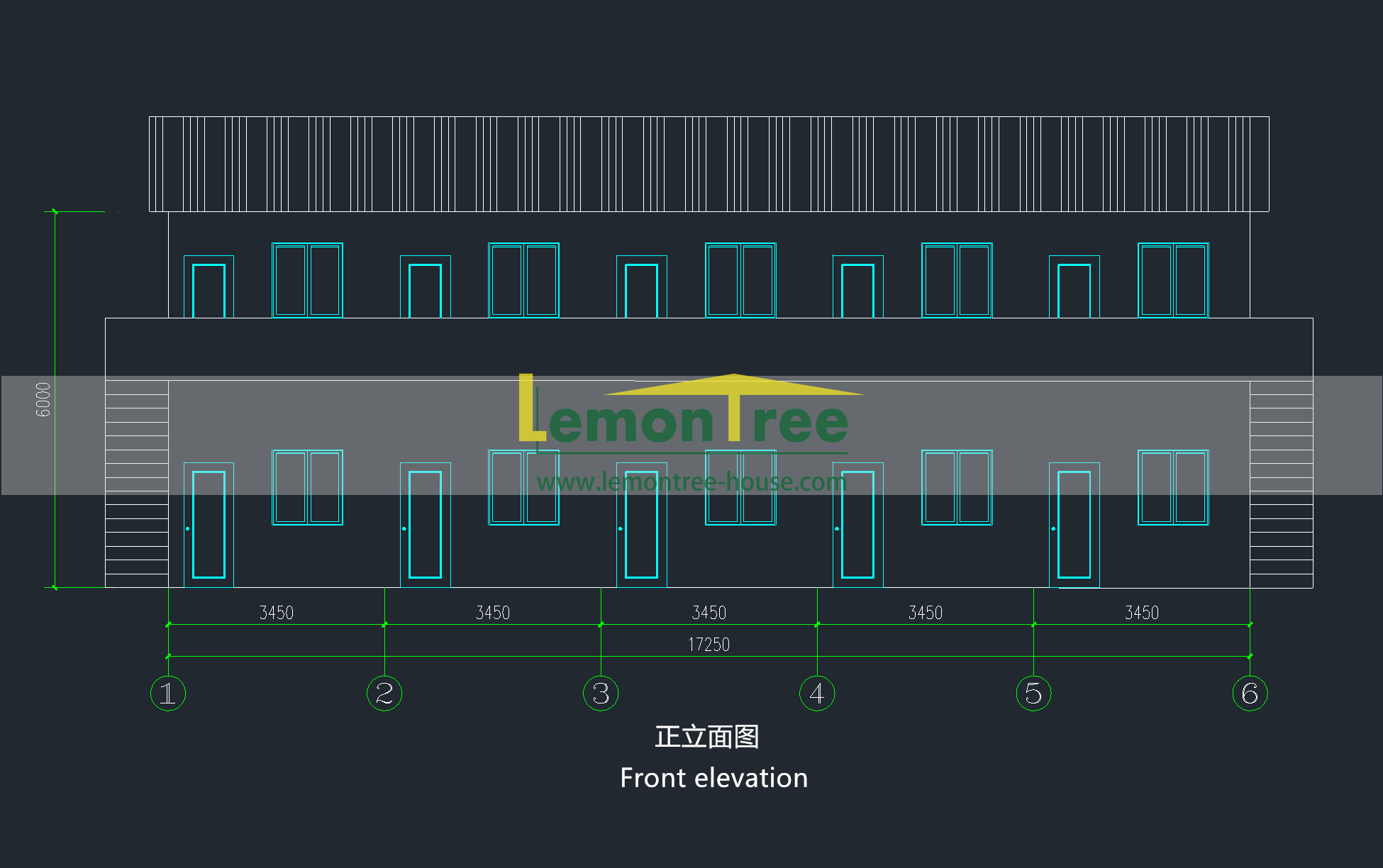

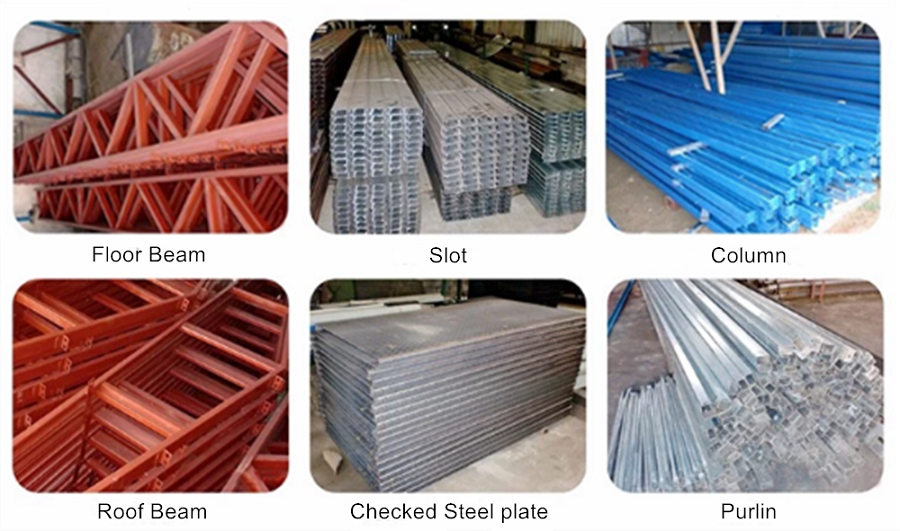

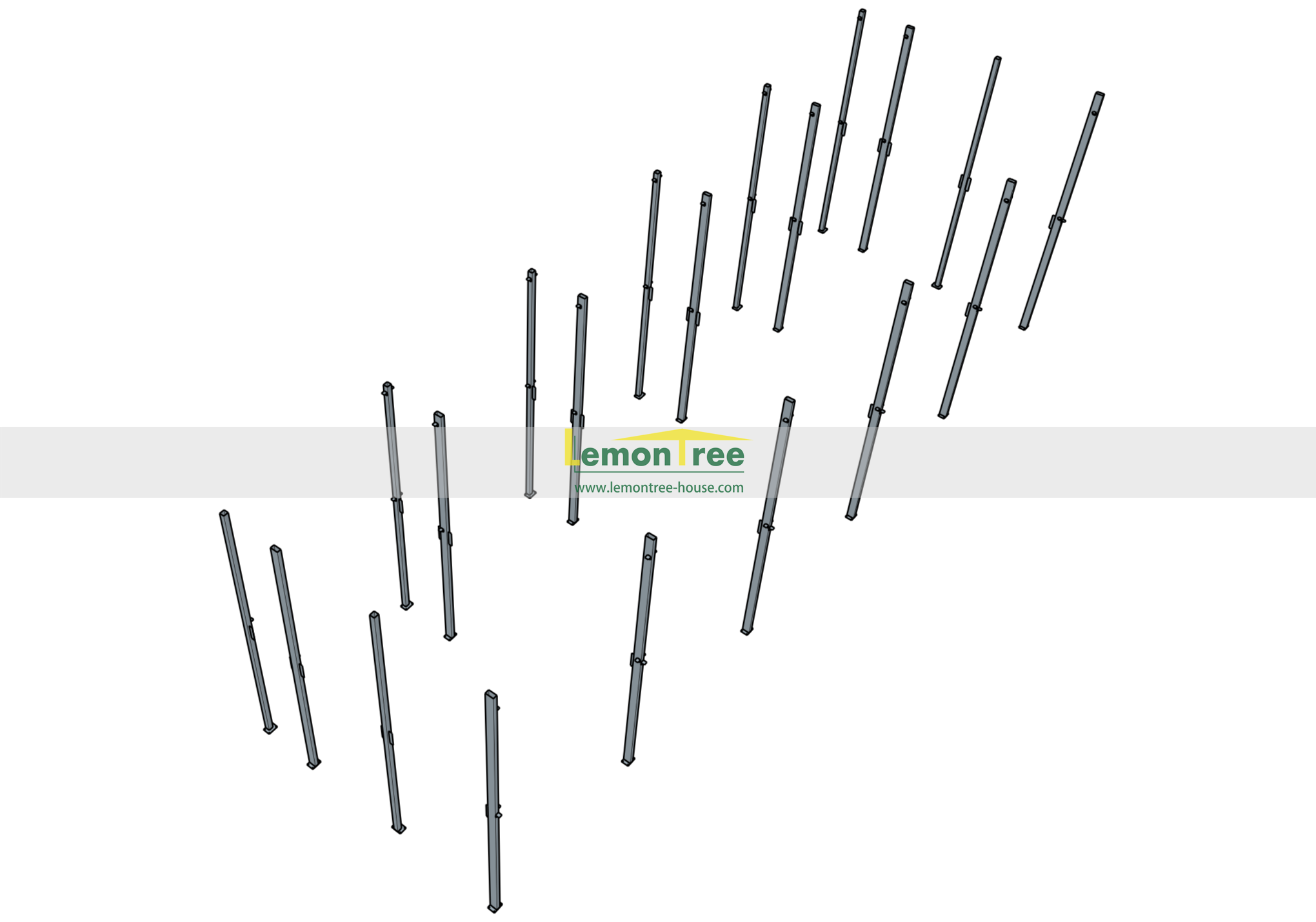

1)Stand column: □100x100x3.0;□100x150x3.0;□100x200x3.0

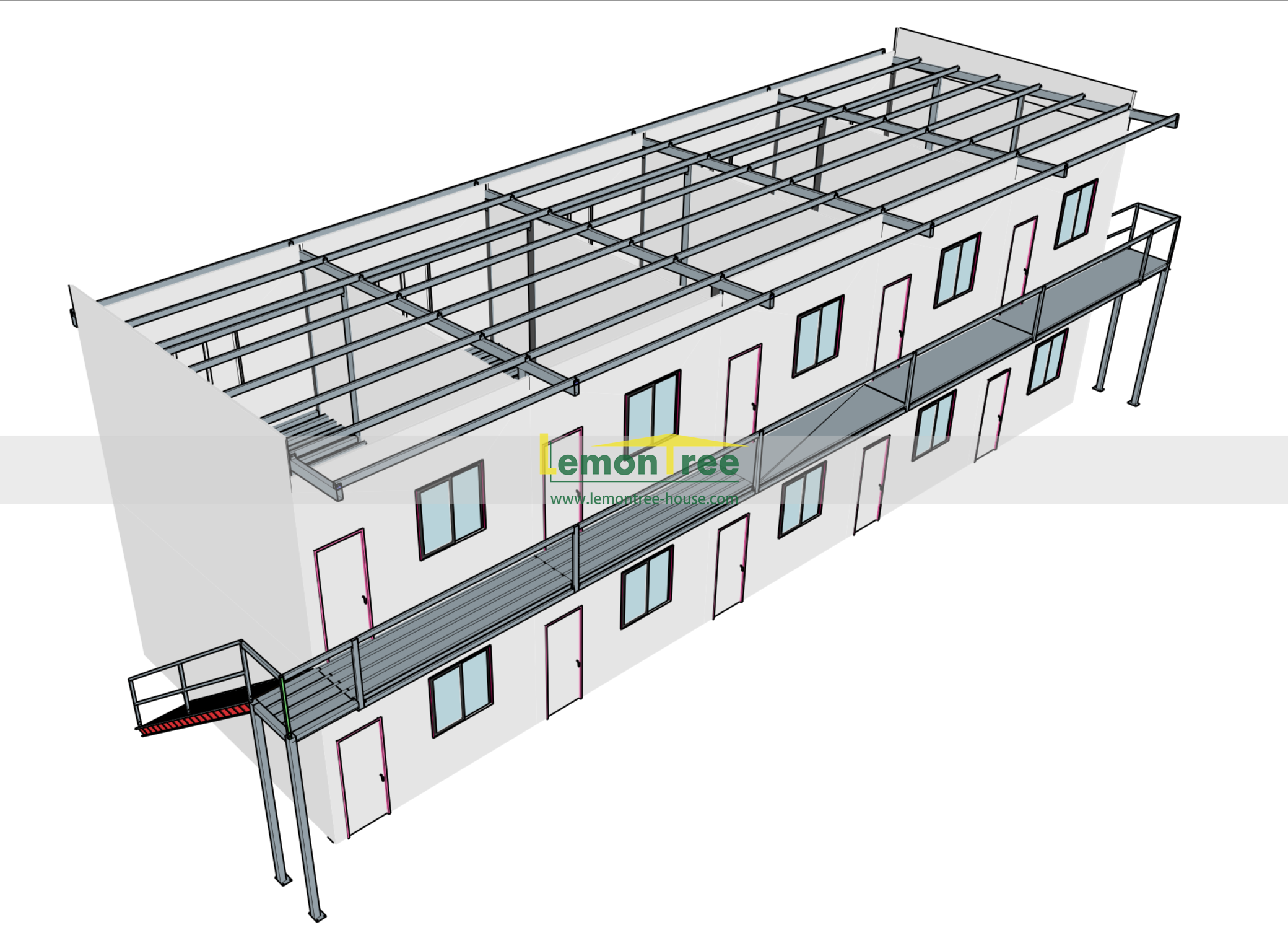

2)Roof beam: □100x150x3.0;□120x60x3.0;C80x2.0+C50x30x1.3

3)Floor beam: C80x2.0 + C50x30x2.0;□100x200x3.0

4)Ring beam: □100x100x3.0;□80x80x3.0

5)Horizontal support: L 50x3.0;

6)Floor purlin: C120x2.0;C100x2.0; Galvanized raw color.

7)Roof purlin: C80x2.0;C100x2.0;□80x40x2.0; Galvanized raw color.

8)Aisle board: Checked plate 2.3mm thk;

9)Staircase: C 160x2.5 & checked plate 2.3mm thk;

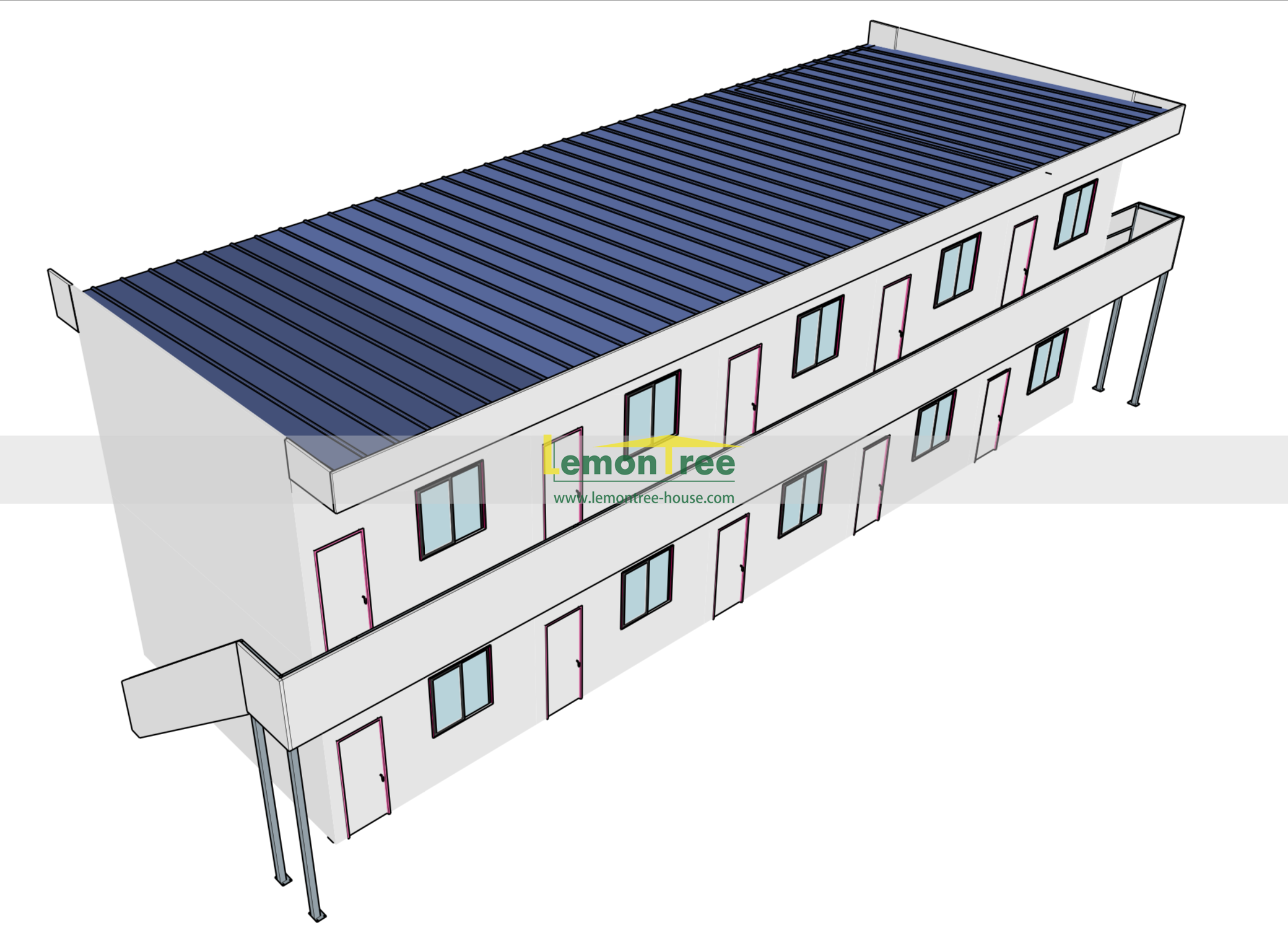

10)Glass wool sandwich wall panel: 50mm thk; density: 38kg/m³, steel plate thk 0.376mm;

11)Glass wool sandwich tile panel: 50mm thk; density: 35kg/m³, steel plate thk 0.376mm;

12)Partition slot: aluminum slot 1.0mm thk;

13)Hemming: thk 0.376mm blue color steel.

14)Floor board: thk 15~18mm plywood; (or thk 15-18mm cement fiber board )

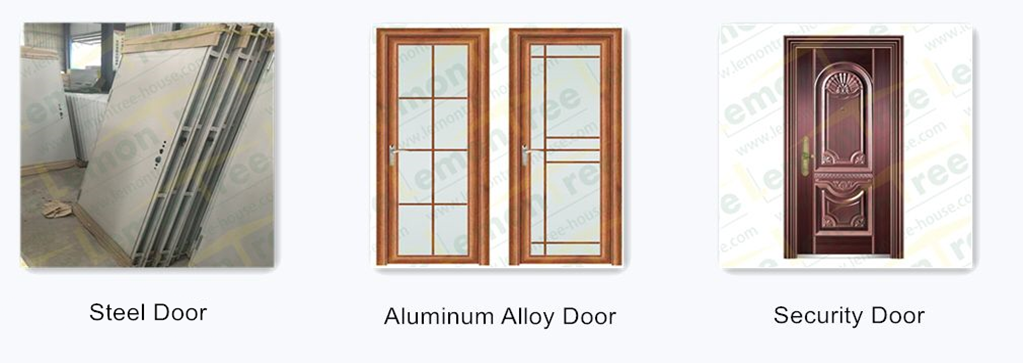

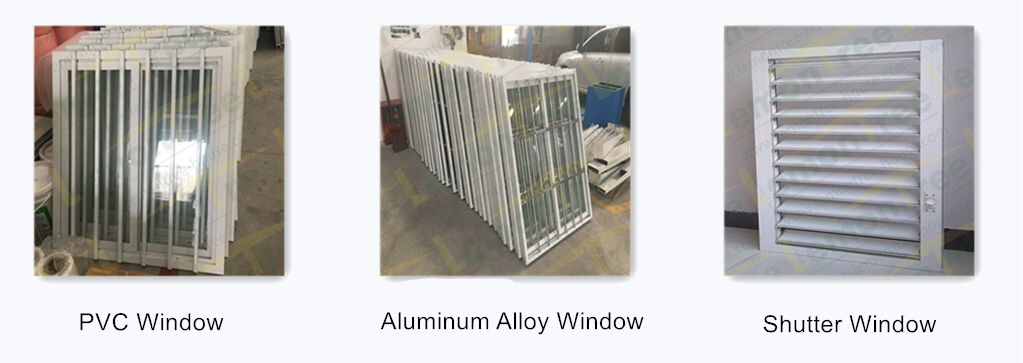

15)PVC window & Sandwich door.

Due to all components of Modular prefab T house are separate, we would pack all the materials and put them in the counter as possible as we can. In general, One 40HQ shipment container can be loaded 200~300 square meters of materials. If you have any requirements about packing, you can communicate with us when ordering.

1)-Set the foundation as drawing, then start to erect the columns firstly.

2)-Install the ring beams to keep the structure stably.

3)- Set the floor beams & roof beams. (This kind of roof beams included the canopy structure)

4)-Assemble the stair brackets, then put on the floor purlins & the roof purlins.

5)-Assemble the staircase structure and set the aisle boards & the railing.

6)-Set the floor board and fix in the wall panels, at the same time fix the windows & doors.

7)-Fix the roof tiles, the covered-edges for the roof structure.

8)-Install sandwich panels for the railing of staircase & aisle. (Others installation, fixed the rivets and sealed the gaps by glass glue.)

Here are the catalogs from Lemon Tree, welcome to download them after leave your basic info.

Hope our professional will helpful for yours.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.