Here are the catalogs from Lemon Tree, welcome to download them after leave your basic info.Hope our professional will helpful for yours.

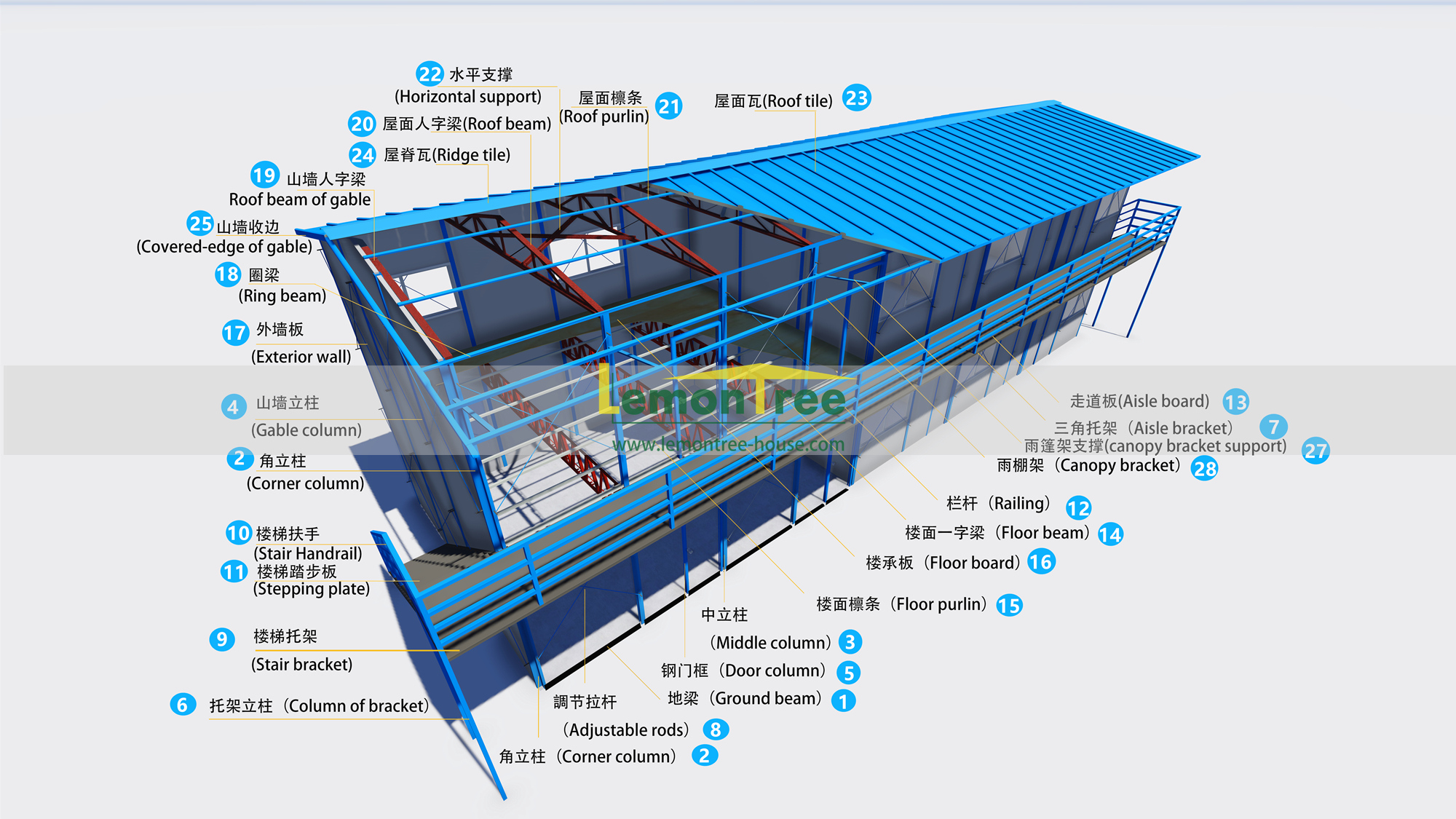

Advantage: Modular K prefab house, adopted light steel framing as its bearing structure, surrounded by sandwich panels of wall and roof. At the basic of design concept of K-house products are universally, standardization and modular, it totally achieved the advantages of temporary buildings such as serialization development, industrialization production, matching supply, assemble & dismantle quickly and many time of reusing. Convenient to installation, with the best cost performance.

Modular Prefab K House

Application: It is widely applied to use as temporary house for engineering camps, government arrangement buildings, large-scale games and commercial events, etc.

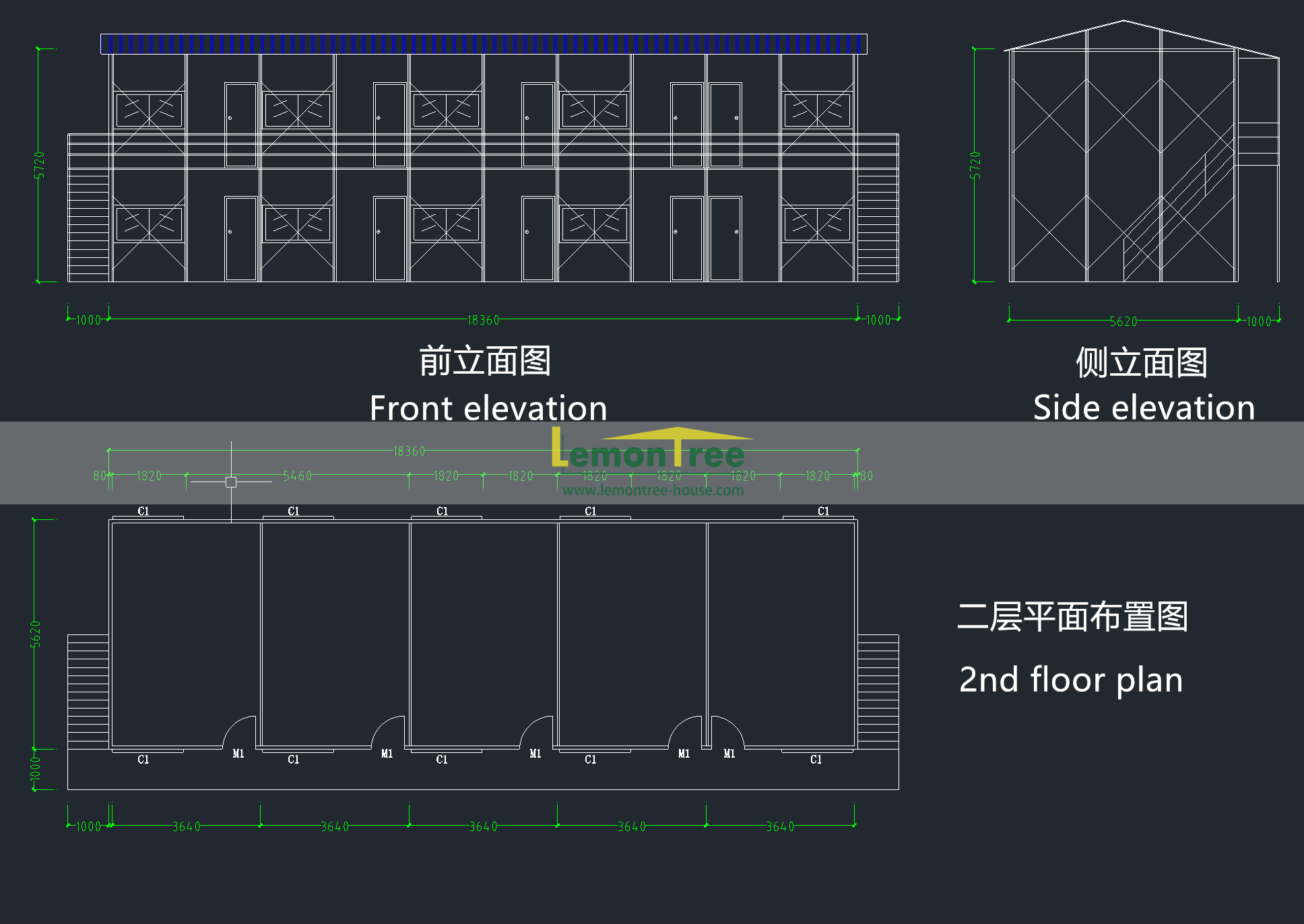

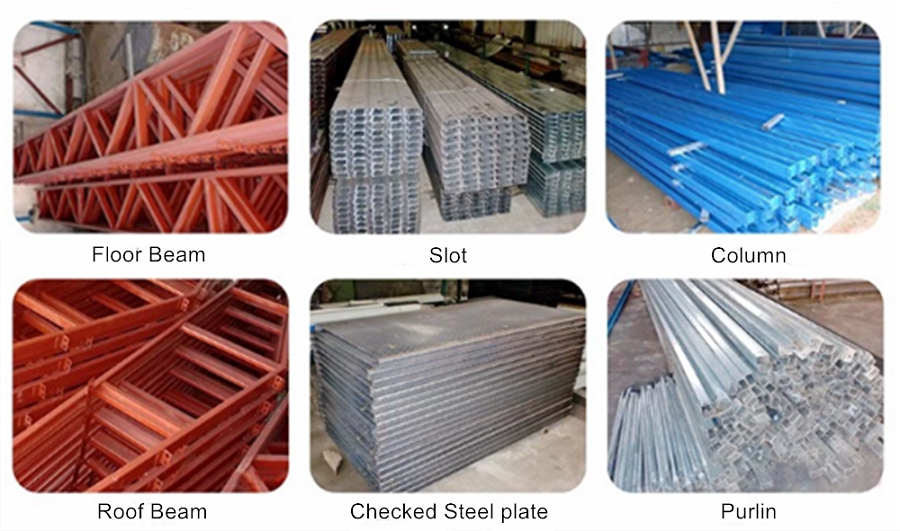

Here is a basic material list for Prefabricated K-house for reference.

Due to all components of Modular prefab K house are separate, we would pack all the materials and put them in the counter as possible as we can. In general, One 40HQ shipment container can be loaded 200~300 square meters of materials. If you have any requirements about packing, you can communicate with us when ordering.

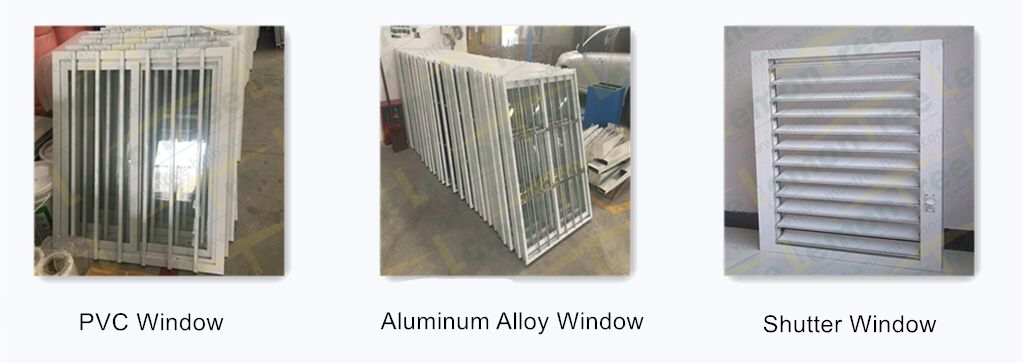

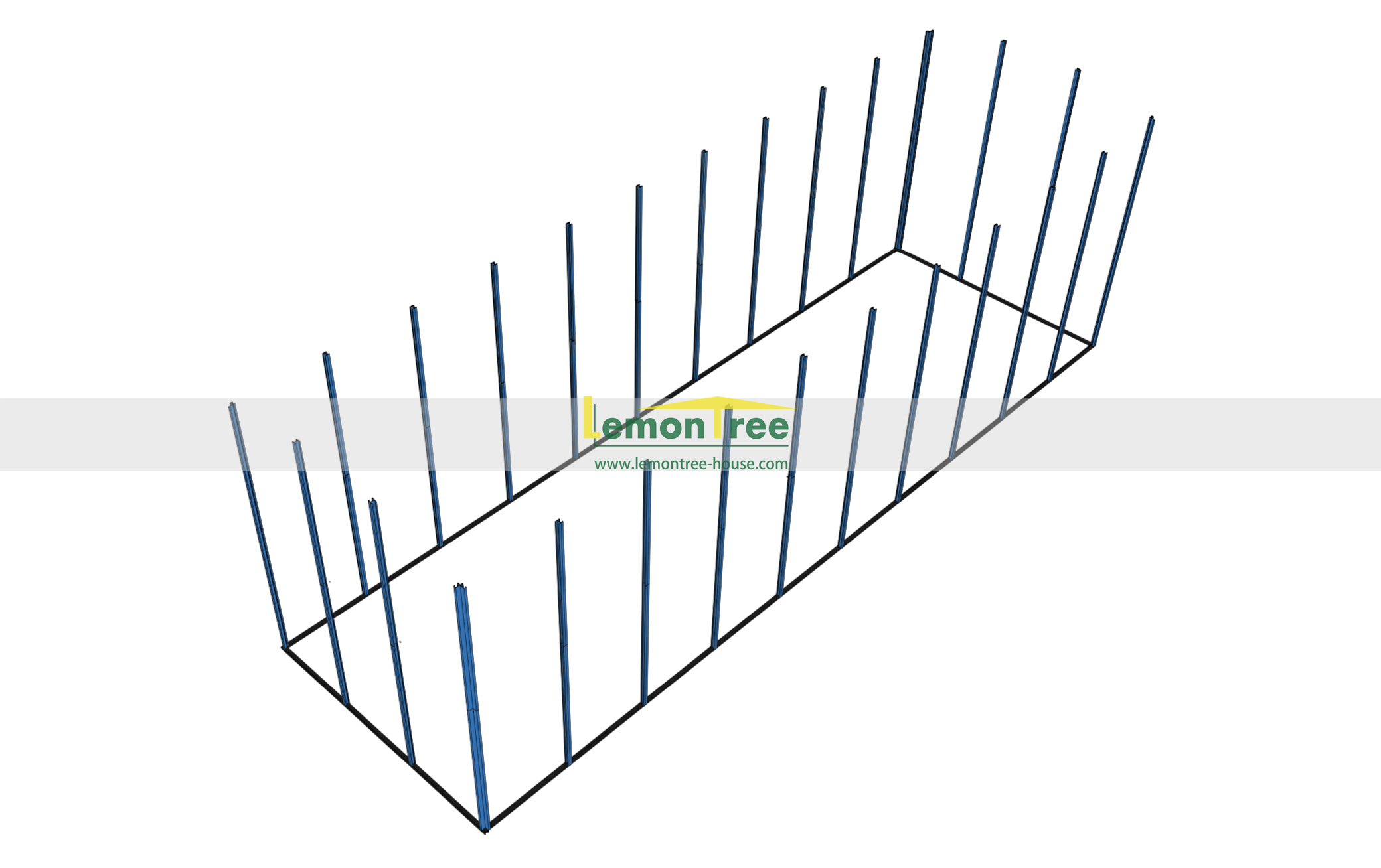

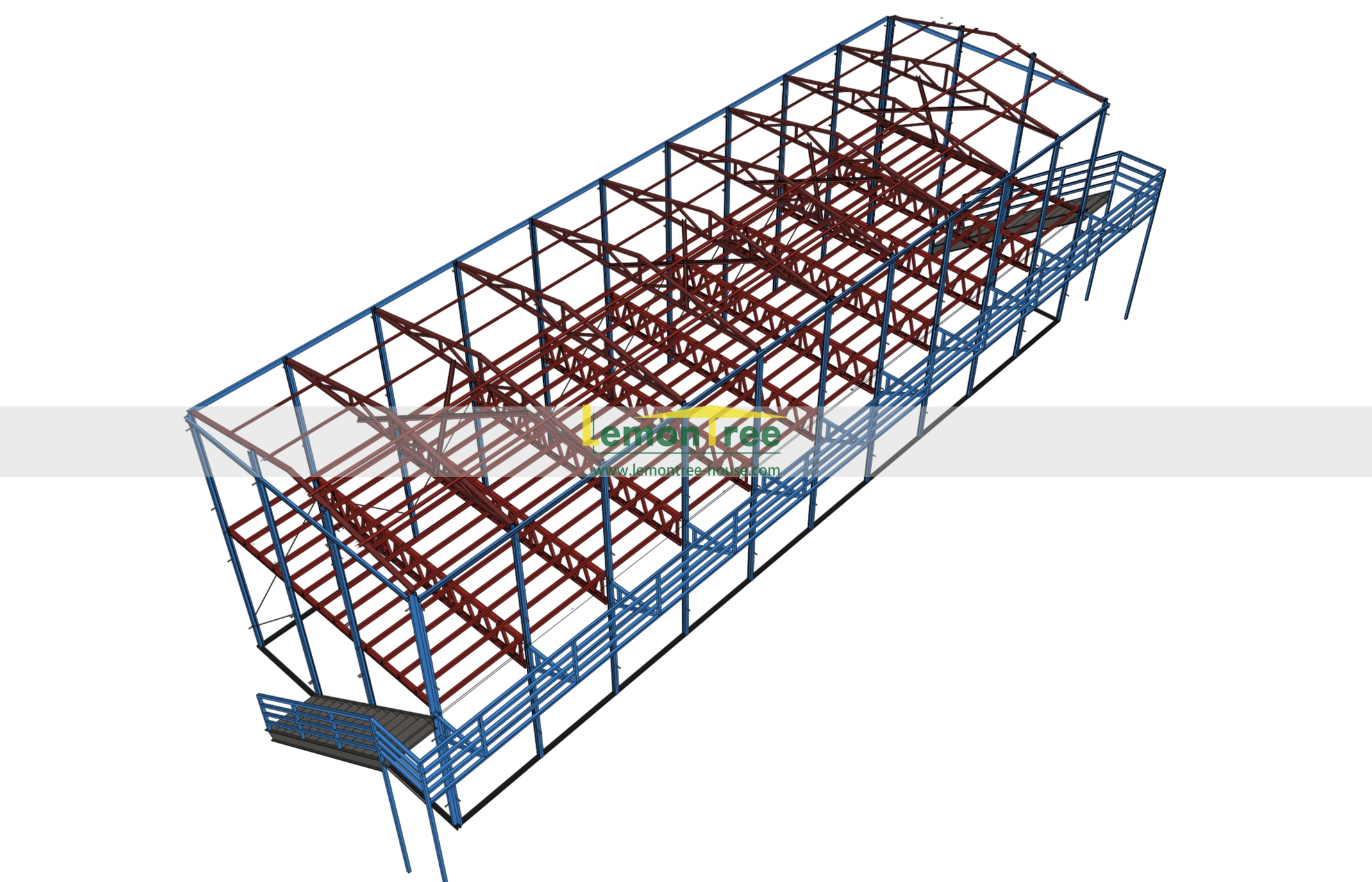

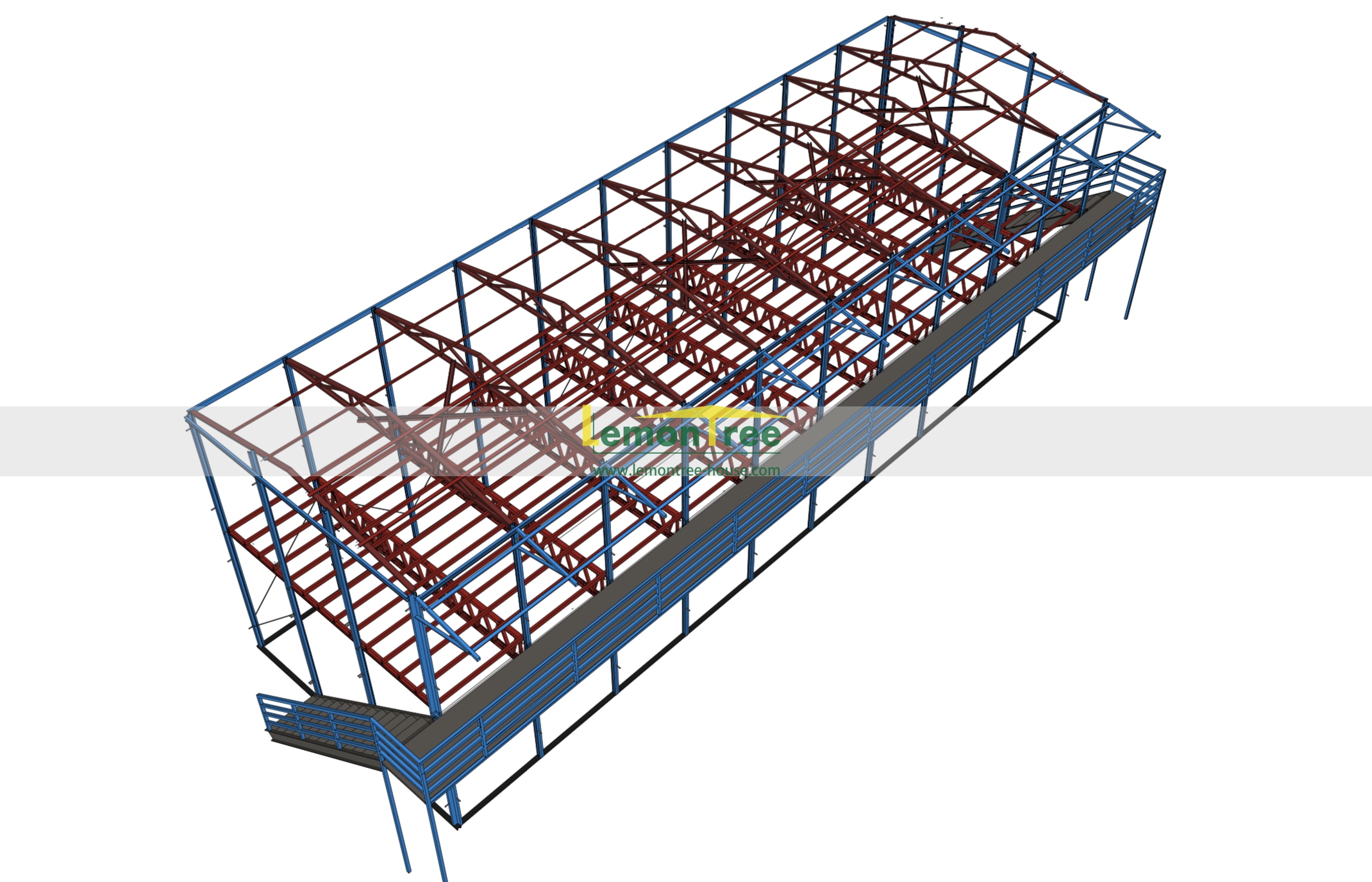

1)-Set the foundation as drawing. Place the ground beams & erect the columns.

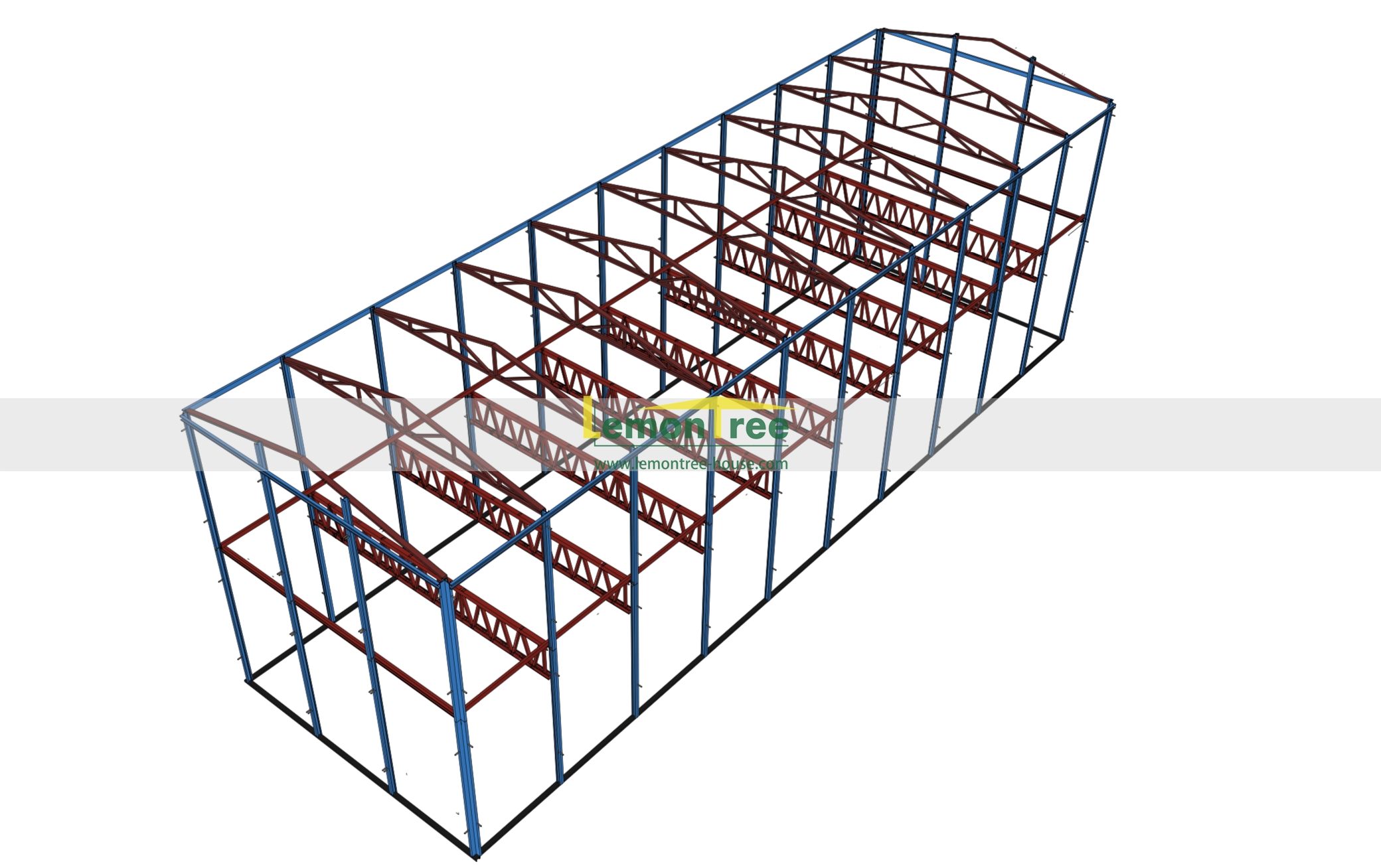

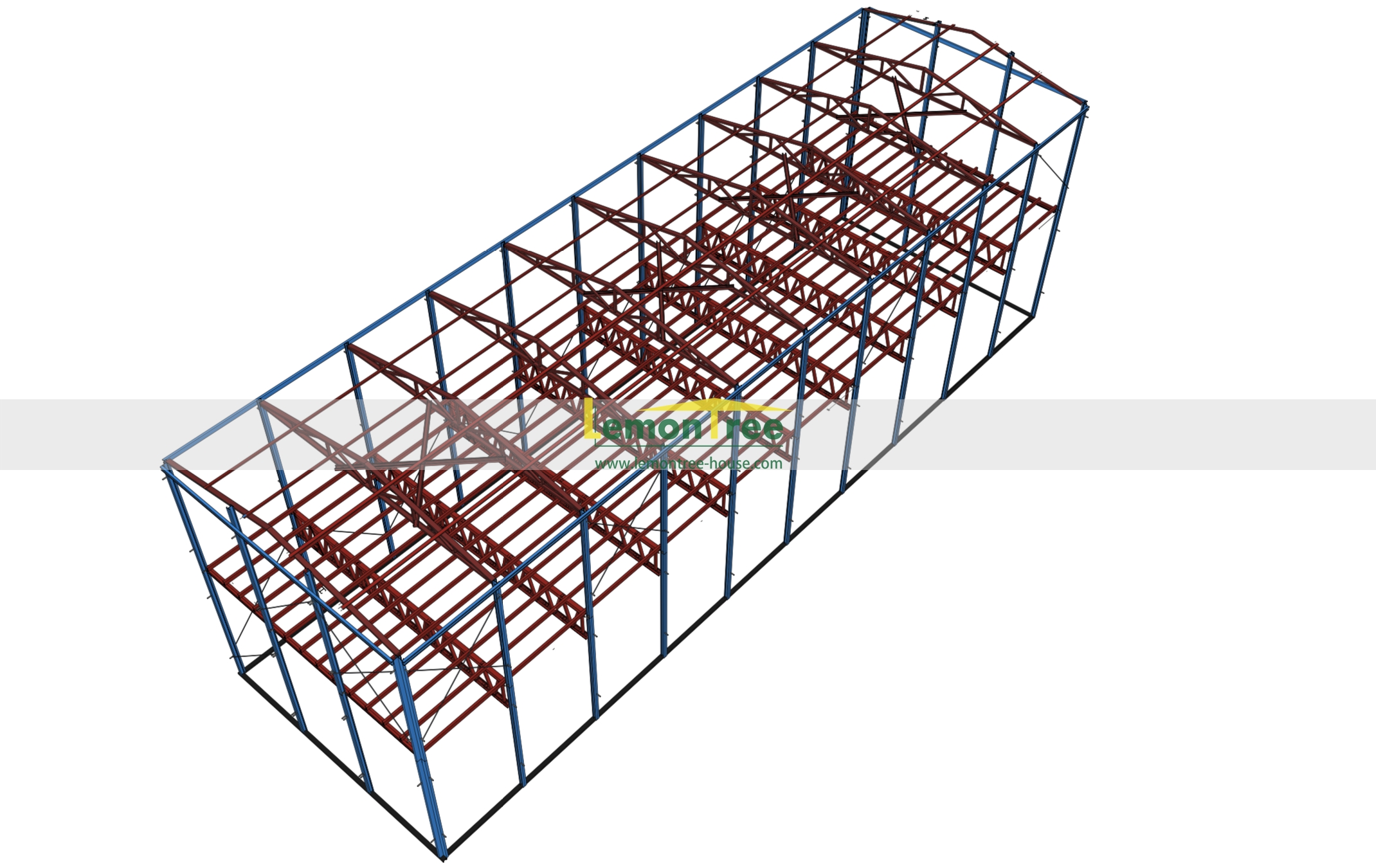

2)-Install ring beams of the roof & the floor to stable the frame, and then set the floor beams and roof beams.

3)- Install the purlins of the floor & the roof, later set the lateral supports to the roof beams.

4)- Install aisle brackets firstly, then for the stair platform brackets, the two staircases of both sides and all of the railings.

5)-Put the aisle boards on and install the canopy bracket & supports.

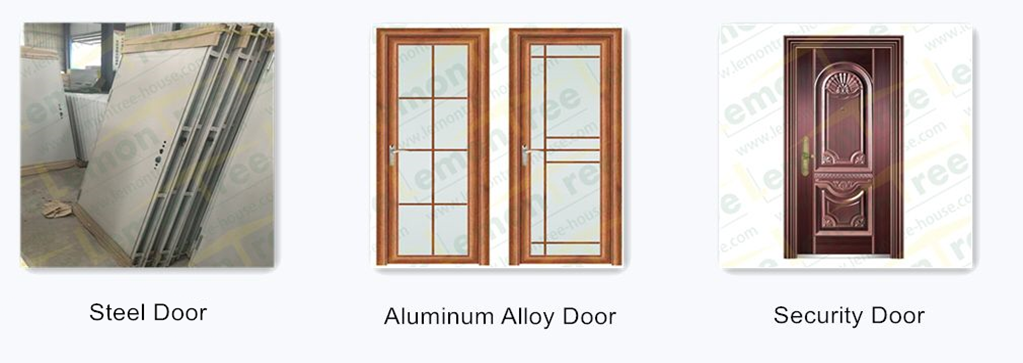

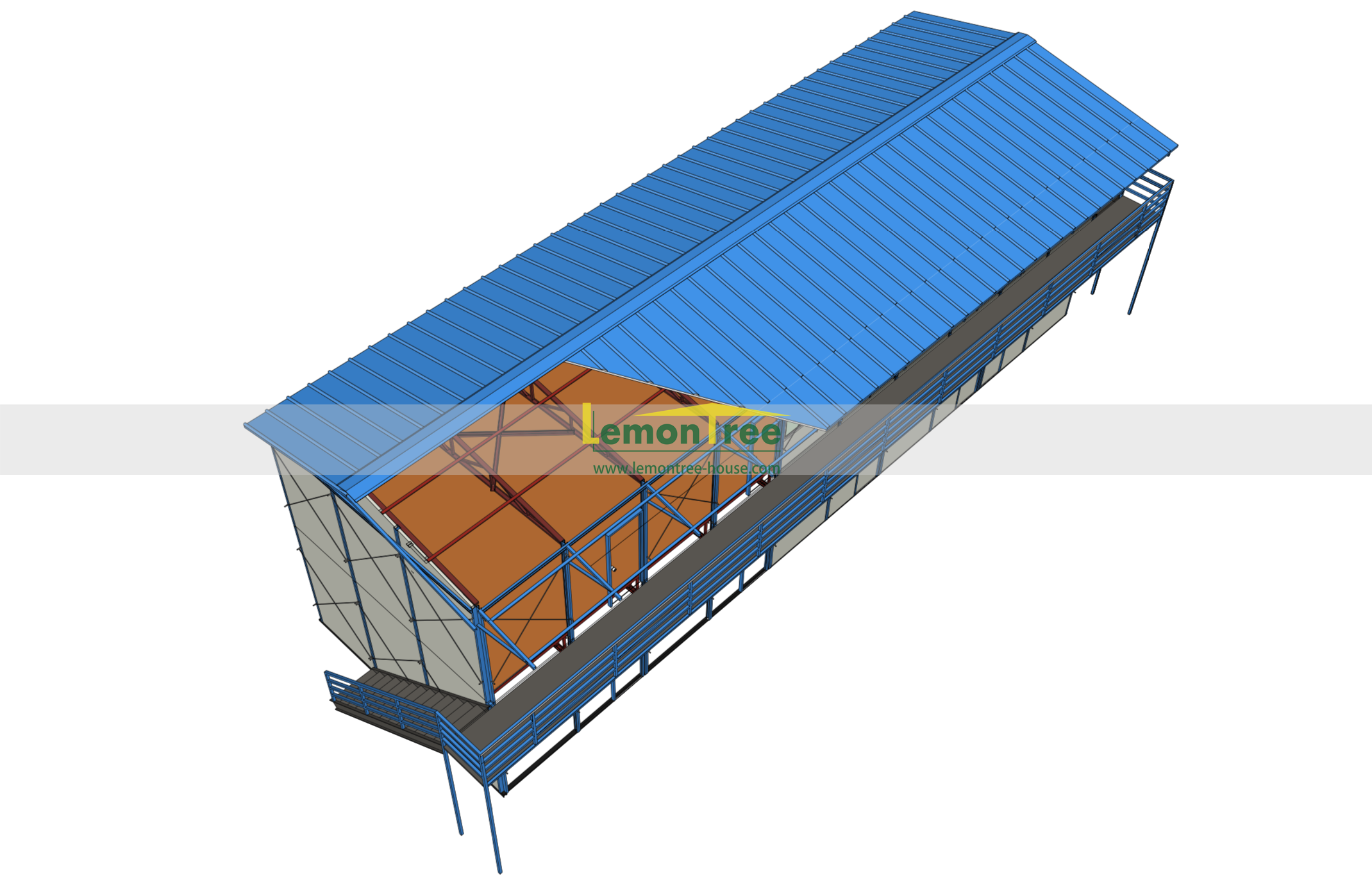

6)-Assemble the door frames, erect the a number parts of sandwich wall panels, doors and windows at the same time. ( Don’t fix all of the wall panels at first, leave some entrance for moving the floor boards into K-house)

7)-Set the floor boards on and finish to fix the rest of wall panels, and later install all of adjustable rods.

8)-Install the roof tiles, canopy panels, ridge coverings and covered-edges of roof by rivets & glues.

9)-Others installation, such as installing the partition walls, fixed the interior skirting and sealed the gaps by glues.

Here are the catalogs from Lemon Tree, welcome to download them after leave your basic info.

Hope our professional will helpful for yours.

Please make sure your contact information is correct. Your message will be sent directly to the recipient(s) and will not be publicly displayed. We will never distribute or sell your personal information to third parties without your express permission.